Better dimensional and weather stability than wood, lighter than concrete Railroad builders are turning increasingly to polyurethane composite marketed under the name Eslon Neo Lumber FFU from SEKISUI CHEMICAL CO. LTD., Tokyo as the material of choice for manufacturing the ties or sleepers that are used to support railroad tracks. The material is noted for the far greater durability of the ties and the correspondingly lower lifecycle costs. In Tokyo, plastic ties have been in service for more than a quarter of a century. They have been laid, for example, under the track for the Shinkansen high-speed train, and the FFU (Fiber reinforced Foamed Urethane) polyurethane ties have now been premiered in Germany.

Railroad ties must be able to withstand high mechanical loads and must also be dimensionally stable and weather-resistant over a long period to comply with the conditions for safe rail operation and low maintenance costs. Frequent temperature changes, radiation and moisture start to affect wooden ties after a relatively short time, and repairing the wooden track involves a considerable amount of material, time, organization and cost. In comparison polyurethane ties have an estimated service life of at least 50 years. With considerably longer maintenance cycles and associated cost benefits for the railroad operator, individual ties can be replaced quickly and accurately, helping to lower construction costs even further.

The flexural strength of the polyurethane ties is also very much higher than that of wood, even after 15 years, the material is also suitable for the construction of high-speed tracks.

The polyurethane material looks like wood and combines all the positive properties of the natural product with those of a modern composite product. The polyurethane ties can be processed in the same way as timber, and compared with concrete, the polyurethane material weighs much less and boasts the reproducible evenness that is important with turnouts. The polyurethane ties are also very suitable for bridges due to their lightweight and they can be manufactured in virtually any desired length and cross-section up to a current maximum of 9.60 meters.

The ecological compatibility of the polyurethane ties is also an advantage. As a rule, ties that have already been in service can be reused, or can be recycled in the same way as the production scrap.

The polyurethane system based on long-fiber reinforced Baydur® 60 integral skin foam comes from Sumika Bayer Urethane Co., Ltd., the Japanese polyurethane systems house in Bayer MaterialScience’s global BaySystems® network.

Polyurethane in railroad ties, increases durability, safety and decreases cost.

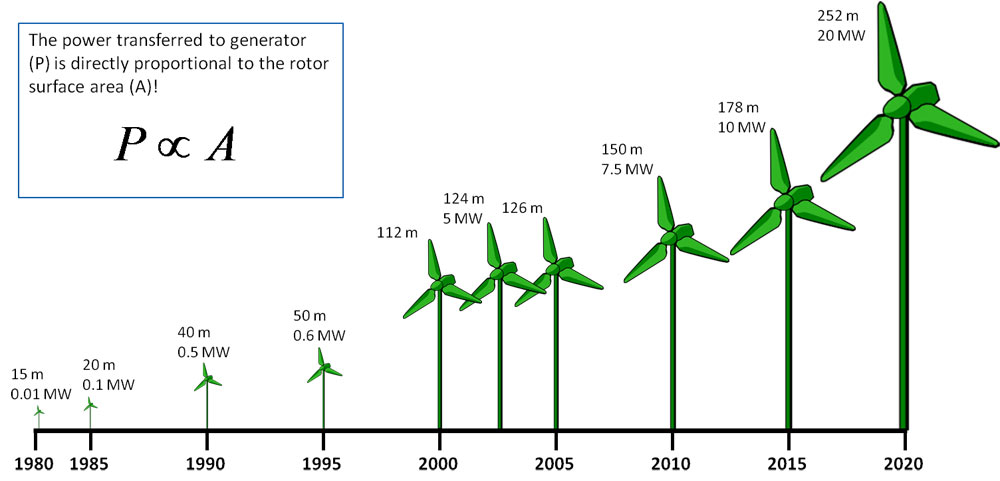

What does this all mean, you ask? The lighter, stiffer blades enabled by the usage of polyurethane allow us to maximise energy production as it permits the construction of larger wind turbines. As the blades also improve on levels of fatigue and fracture toughness, it ensures the blades ability to withstand the stress of high winds. These bigger, stronger blades in turn capture greater amounts of wind energy compared to traditional turbines. According to EWEA, “the blades should [also] be economically feasible, using sustainable materials”; the polyurethane prototype contains “low, or no, volatile organic compounds (VOCs) and use sustainable raw materials from renewable resources”. Studies on the prototype have shown that the technology “can even be “retrofitted into existing designs at minimal cost”.

What does this all mean, you ask? The lighter, stiffer blades enabled by the usage of polyurethane allow us to maximise energy production as it permits the construction of larger wind turbines. As the blades also improve on levels of fatigue and fracture toughness, it ensures the blades ability to withstand the stress of high winds. These bigger, stronger blades in turn capture greater amounts of wind energy compared to traditional turbines. According to EWEA, “the blades should [also] be economically feasible, using sustainable materials”; the polyurethane prototype contains “low, or no, volatile organic compounds (VOCs) and use sustainable raw materials from renewable resources”. Studies on the prototype have shown that the technology “can even be “retrofitted into existing designs at minimal cost”.